Aerospace engineering involves some of the most complex and critical design challenges, requiring precision, reliability, and performance. NASTRAN, developed by NASA and now maintained by Siemens, has become a cornerstone in the aerospace industry for structural analysis. This in-depth guide explores how NASTRAN simplifies aerospace engineering, its key features, and its applications in real-world scenarios.

Introduction to NASTRAN 🚀

NASTRAN (NASA Structural Analysis) is a powerful finite element analysis (FEA) software used extensively in aerospace engineering. It provides comprehensive solutions for static and dynamic analysis, ensuring the structural integrity and performance of aerospace components.

Key Features of NASTRAN 🔧

- Advanced Solvers

- Static Analysis: Evaluate the structural response under static loads to ensure safety and performance.

- Dynamic Analysis: Perform modal, frequency, and transient response analyses to predict the behavior under dynamic conditions.

- Nonlinear Analysis: Handle large deformations, material nonlinearities, and complex contact conditions.

- Optimization Capabilities

- Topology Optimization: Optimize the material layout within a given design space to achieve the best structural performance with minimal weight.

- Shape and Size Optimization: Refine the geometry and dimensions of components to meet performance criteria.

- Thermal Analysis

- Steady-State and Transient Thermal Analysis: Simulate the thermal response of components to ensure they can withstand operating temperatures.

- Aeroelasticity

- Flutter Analysis: Assess the stability of structures subjected to aerodynamic forces to prevent catastrophic failure.

- Aeroelastic Analysis: Evaluate the interaction between aerodynamic forces and structural flexibility.

- High-Performance Computing (HPC)

- Parallel Processing: Utilize HPC resources to handle large and complex models efficiently, reducing computation time.

Applications in Aerospace Engineering ✈️

- Aircraft Structural Analysis

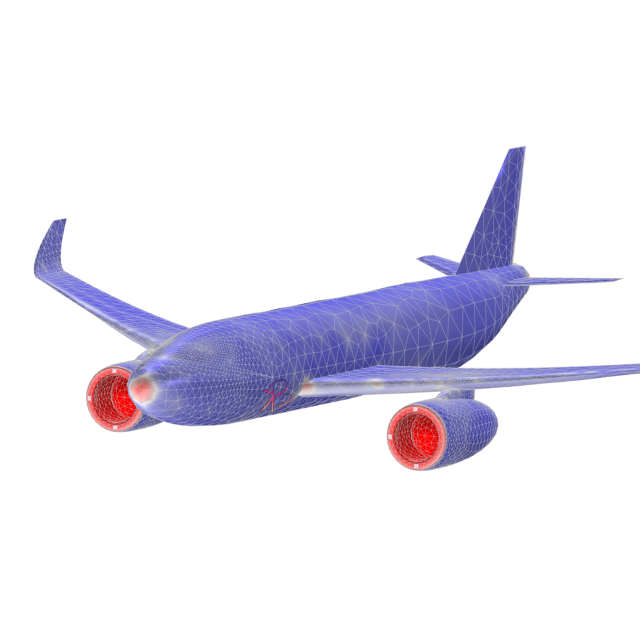

- Wing and Fuselage Design: Analyze and optimize the structural components of wings and fuselages to ensure they can withstand aerodynamic loads and stresses during flight.

- Landing Gear Analysis: Evaluate the strength and durability of landing gear under various landing conditions.

- Spacecraft Engineering

- Satellite Structures: Perform structural and thermal analyses on satellite components to ensure they can survive the harsh conditions of space.

- Rocket Components: Analyze the structural integrity of rocket stages and payload fairings to ensure safe launch and deployment.

- Helicopter Dynamics

- Rotor Blade Analysis: Assess the dynamic behavior of rotor blades under various operating conditions to ensure stability and performance.

- Vibration Analysis: Perform vibration analysis to identify and mitigate potential issues that could affect the helicopter’s performance and safety.

There is a good book on Fundamentals of Helicopter Dynamics

Real-World Case Studies 🌍

- Optimizing Aircraft Wing Design

- Challenge: An aerospace company needs to design a lightweight yet strong wing structure for a new commercial aircraft.

- Solution: Using NASTRAN, engineers perform static and dynamic analyses to optimize the wing's structure, reducing weight while ensuring it meets all safety and performance requirements.

- Outcome: The optimized wing design leads to improved fuel efficiency and overall performance of the aircraft.

- Thermal Analysis of Satellite Components

- Challenge: A satellite manufacturer needs to ensure their components can withstand the extreme thermal conditions of space.

- Solution: Engineers use NASTRAN to perform steady-state and transient thermal analyses, identifying potential thermal stresses and optimizing the design to mitigate them.

- Outcome: The satellite components are validated to survive the harsh space environment, ensuring reliable operation throughout the mission.

- Aeroelastic Analysis of Helicopter Rotor Blades

- Challenge: A helicopter manufacturer needs to ensure their rotor blades remain stable and perform efficiently under aerodynamic loads.

- Solution: Using NASTRAN, engineers conduct aeroelastic and flutter analyses to evaluate the interaction between aerodynamic forces and the rotor blade structure.

- Outcome: The analysis helps in optimizing the rotor blade design, ensuring stability and enhancing the helicopter's performance and safety.

Tips for Maximizing the Use of NASTRAN ✨

- Leverage High-Performance Computing

- Utilize HPC resources to run large and complex simulations more efficiently, reducing computation time and enhancing productivity.

- Integrate with CAD Tools

- Seamlessly integrate NASTRAN with CAD software to streamline the design and analysis workflow, ensuring consistency and accuracy in your models.

- Continuous Learning and Training

- Stay updated with the latest features and best practices by participating in training sessions, webinars, and engaging with the NASTRAN user community.

- Perform Sensitivity Analysis

- Conduct sensitivity analyses to understand how different parameters affect the structural performance, helping in making informed design decisions.

- Optimize Early in the Design Process

- Incorporate optimization techniques early in the design process to identify and address potential issues before they become costly to fix.

Conclusion 🎓

NASTRAN simplifies aerospace engineering by providing robust tools for structural, thermal, and dynamic analysis. Its advanced solvers, optimization capabilities, and integration with high-performance computing make it an indispensable tool for aerospace engineers. By leveraging NASTRAN, engineers can ensure the safety, reliability, and performance of aerospace components, from aircraft wings to satellite structures, driving innovation and excellence in the industry.

Discussions? let's talk here

Check out YouTube channel, published research

you can contact us (bkacademy.in@gmail.com)

Interested to Learn Engineering modelling Check our Courses 🙂

All product names, trademarks mentioned in this article are the property of their respective owners. This content is for educational purposes only and is not affiliated with, endorsed by, or sponsored by any software company. For official information, please visit the respective official websites. The views expressed are those of the author ONLY.