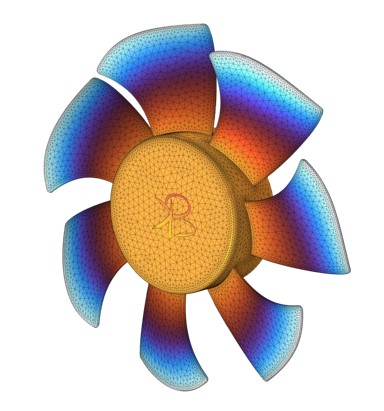

Mesh Tips for Advanced Simulations - In advanced simulations using COMSOL Multiphysics, the mesh quality and configuration can significantly influence the accuracy and efficiency of your results. This blog will delve into specific techniques and considerations for optimizing your mesh for high-fidelity simulations.

Interested to Learn Engineering modelling? Check our Courses?

Understanding Mesh Types in COMSOL

COMSOL Multiphysics offers several types of meshes, each suited for different kinds of simulations. Understanding these mesh types is critical for selecting the appropriate one for your simulation needs:

- Free Tetrahedral Mesh: Ideal for complex geometries and 3D simulations, providing good flexibility and control.

- Free Triangular Mesh: Used primarily for 2D geometries, offering a balance between computational efficiency and accuracy.

- Structured Mesh (Quad, Hex): Suitable for regular geometries, enabling more precise control over element distribution.

- Boundary Layer Mesh: Essential for simulations involving fluid flow and heat transfer near walls, capturing boundary layer effects accurately.

Mesh Refinement Strategies

Refining your mesh is crucial for capturing the fine details and gradients in your simulations. Here are some strategies for effective mesh refinement:

- Adaptive Mesh Refinement: Utilize COMSOL's adaptive mesh refinement feature, which automatically refines the mesh based on error estimates during the solution process. This ensures that regions requiring higher resolution receive finer mesh elements.

- Local Mesh Refinement: Manually refine the mesh in regions of interest, such as areas with high gradients, sharp corners, or critical interfaces. Use boundary layers, edge refinement, and point refinement tools to achieve this.

- Physics-Controlled Meshing: Enable physics-controlled meshing to automatically generate a mesh that is optimized for the specific physics involved in your simulation. This approach leverages COMSOL's built-in heuristics to balance accuracy and computational load.

Ensuring Mesh Quality

High-quality mesh is characterized by elements that are not too skewed, have uniform size distribution, and do not lead to excessively high aspect ratios. Here are some tips to ensure mesh quality:

- Aspect Ratio Control: Maintain a low aspect ratio for mesh elements, especially in critical regions. High aspect ratios can lead to numerical inaccuracies and convergence issues.

- Skewness and Distortion: Monitor and minimize skewness and distortion of mesh elements. COMSOL provides quality metrics for skewness and element quality that can be used to assess and improve mesh integrity.

- Mesh Smoothing: Apply mesh smoothing techniques to improve the distribution and quality of mesh elements. This can be particularly useful after performing local refinements.

Mesh Independence Study

A mesh independence study involves running your simulation with progressively finer meshes until the results converge. This study helps ensure that your results are not unduly influenced by the mesh resolution. Follow these steps:

- Initial Coarse Mesh: Start with a relatively coarse mesh and perform the simulation.

- Progressive Refinement: Gradually refine the mesh and re-run the simulation, noting the changes in key results (e.g., stress, temperature, velocity).

- Convergence Check: Plot the results against mesh density and look for a plateau where further refinement does not significantly alter the results. This indicates mesh independence.

Advanced Meshing Techniques

For more complex simulations, consider these advanced meshing techniques:

- Hybrid Meshing: Combine different mesh types within the same model. For example, use a structured mesh in regular regions and an unstructured mesh in complex regions. This hybrid approach can improve both accuracy and computational efficiency.

- Mesh Import and Export: If you have a specific mesh generated in another software, you can import it into COMSOL using standard mesh file formats. Similarly, you can export the mesh from COMSOL for further analysis or modification.

- Custom Mesh Generation: Use COMSOL’s Application Programming Interface (API) to script custom mesh generation routines. This allows for precise control over mesh parameters and distribution, tailored to your specific simulation needs.

Practical Example: Meshing a Heat Sink

To illustrate these techniques, let's consider meshing a heat sink for a thermal simulation:

- Geometry Setup: Import the heat sink geometry and identify critical regions such as the base, fins, and contact interfaces.

- Initial Mesh: Start with a free tetrahedral mesh for the entire geometry.

- Local Refinement: Refine the mesh near the base and fin tips, where high thermal gradients are expected. Apply boundary layer meshing around the fins to capture the thermal boundary layer.

- Mesh Quality Check: Assess the aspect ratio, skewness, and element quality metrics. Adjust the mesh accordingly using smoothing and local refinement tools.

- Mesh Independence Study: Perform a mesh independence study by refining the mesh iteratively and checking the convergence of temperature distribution and heat flux.

Conclusion

Optimizing the mesh in COMSOL Multiphysics is a crucial step in ensuring accurate and efficient simulations. By understanding the different mesh types, applying refinement strategies, ensuring mesh quality, and conducting a mesh independence study, you can achieve high-fidelity results in your advanced simulations. Employ advanced techniques like hybrid meshing and custom mesh generation to further enhance your simulation accuracy and efficiency. By following these guidelines, you can harness the full potential of COMSOL’s meshing capabilities and achieve superior results in your simulations.

You can check official website for software access and official resources at comsol.com

For help in modelling in any FEA, FDTD, DFT Simulation / Modelling work, you can contact us (bkcademy.in@gmail.com) or in any platform.

Interested to Learn Engineering modelling? Check our Courses?

u can follow us on social media

Share the resource

-.-.-.-.-.-.-.-.-.().-.-.-.-.-.-.-.-.-

© bkacademy

2 replies on “Mesh Tips for Advanced Simulations in COMSOL”

[…] checks: Ensure mesh quality with built-in metrics like aspect ratio and […]

[…] by creating a mapped mesh for simple surfaces. Select the surface and use the "Generate Structured Quad Mesh" option. This […]