Introduction

Finite Element Analysis (FEA) is a numerical simulation technique used to predict how physical systems respond to external stimuli such as mechanical loads, thermal gradients, fluid interactions, and electromagnetic fields. By dividing a system into discrete subdomains—called finite elements—and solving governing equations over each one, FEA transforms complex, real-world behavior into a manageable set of algebraic equations. The rise of computational modeling has made FEA indispensable across research and industry.

In academic and applied research, FEA drives innovation in areas as varied as aerospace design, biomedical engineering, materials science, structural geology, and mechanical systems. With increasing dependence on simulation-based methodologies, FEA is no longer a niche tool but a foundational technology underpinning safer, more efficient, and more sustainable designs. This surge in simulation use aligns with broader technological movements such as digital twin integration and predictive performance modeling.

Background Concepts

At its heart, FEA rests on discretization: complex continuous domains are broken down into smaller finite elements governed by algebraic approximations of physical laws. These elements are connected at nodal points, and their behavior is modeled by applying variational methods and partial differential equations rooted in continuum mechanics.

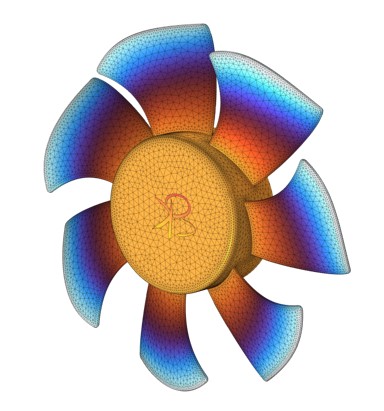

A typical FEA workflow proceeds through three essential stages. Preprocessing involves geometry creation, material definition, and mesh generation. The solver phase calculates responses under boundary conditions and applied loads. Finally, postprocessing visualizes results—typically stress distributions, thermal gradients, or modal frequencies—to interpret physical behavior.

Key to the trustworthiness of FEA outputs is the cycle of validation and verification. Verification ensures that the model accurately solves the governing equations, while validation confirms alignment with physical test data or analytical benchmarks.

Popular tools include ANSYS, Abaqus, COMSOL, Altair HyperWorks, and OpenSees. Each has unique strengths suited to various research domains, as outlined in the following section.

Recent Developments in FEA

Recent years have witnessed a paradigm shift in how FEA is approached and executed. One of the most significant developments is the integration of artificial intelligence and machine learning into traditional workflows. For instance, AI can automate mesh generation, adaptively refine meshes based on stress concentrations, or suggest optimal boundary condition setups.

Additionally, the rise of cloud computing has revolutionized solver deployment. Traditional high-performance computing clusters are being augmented—or even replaced—by scalable cloud solutions. This not only reduces costs but also broadens access to powerful simulations. Engineering.com reports that major institutions now perform multi-million element simulations in hours rather than days.

Digital twins, another emerging field, rely heavily on FEA. By coupling simulation models with real-time sensor data, systems such as turbine engines, bridges, or robotic limbs can be continuously monitored and optimized. This convergence between simulation and reality transforms predictive maintenance and systems diagnostics.

Challenges and Open Questions

Despite its maturity, FEA faces unresolved challenges. A critical concern is the balance between accuracy and computational feasibility. High-fidelity models often require dense meshes, leading to prohibitive simulation times. Adaptive meshing and reduced-order modeling are partial remedies, but not universally applicable.

Another persistent challenge lies in material modeling. Many emerging materials—such as bioinspired composites or nanostructured polymers—exhibit behavior that is nonlinear, anisotropic, and time-dependent. Conventional constitutive models struggle to capture these complexities.

Validation also remains a cornerstone issue. Simulations must be regularly benchmarked against experimental data to ensure their reliability. Yet obtaining accurate material data, especially at micro or meso scales, can be resource-intensive.

Lastly, uncertainty quantification (UQ) has gained traction as a tool to express variability in input parameters or operational conditions. Running multiple simulations with probabilistic inputs enables a statistical understanding of design robustness.

These challenges are non-trivial, yet active areas of research and tool development continue to offer promising solutions.

Opportunities and Future Directions

The future of FEA is increasingly shaped by interdisciplinary convergence. One promising area is multiscale modeling, which couples continuum FEA with atomistic methods such as molecular dynamics. This is especially useful in predicting fracture mechanics or material fatigue from the atomic to structural scale.

Machine learning is expected to continue automating traditionally manual steps. For example, supervised learning models can recommend optimal mesh densities or even generate surrogate models that predict system behavior orders of magnitude faster than full FEA runs.

Sustainability is also a rising concern. FEA plays a critical role in green engineering—whether it’s minimizing material usage, evaluating lifecycle impacts, or ensuring energy-efficient performance. As emphasized in the Gartner 2025 technology trends, sustainable simulation is a growing research priority.

The expanding ecosystem of open-source tools—such as OpenSees and FEniCS—further democratizes simulation access, particularly for small research teams and startups. Combined with scripting customizability, these platforms enable tailored solutions for niche research problems.

Real-World Use Cases

One compelling domain where FEA shines is biomedical engineering. For example, simulation of orthopedic implants helps evaluate stress shielding, bone integration, and implant longevity.

Automotive engineering also benefits immensely. FEA allows virtual crash testing under standardized protocols, significantly cutting down the need for expensive physical prototypes.

In earthquake engineering, tools like OpenSees enable researchers to simulate building responses to seismic events. This facilitates the design of resilient infrastructure, especially in vulnerable regions.

Conclusion

Finite Element Analysis has evolved from a niche numerical tool into a core component of modern research and engineering. Its ability to simulate real-world physical systems with increasing accuracy, fidelity, and speed has made it indispensable in diverse domains ranging from biomechanical design to geotechnical stability. As computational power and algorithmic sophistication continue to grow, FEA is poised to become even more integral to scientific discovery and technological innovation.

Whether the task involves AI-assisted mesh generation, digital twin modeling, or multiscale simulations, FEA offers a versatile framework to navigate the complexity of modern systems. Researchers who stay abreast of these developments will not only refine their designs but contribute to the next generation of simulation-driven breakthroughs.

If you need support feel free to get in touch 🙂.

Check out YouTube channel, published research

you can contact us (bkacademy.in@gmail.com)

Interested to Learn Engineering modelling Check our Courses 🙂

--

All trademarks and brand names mentioned are the property of their respective owners.The views expressed are personal views only.