If you've ever struggled with meshing intricate structures involving multiple domains, joints, circles, and corners, this guide is for you! Let's break down the process step-by-step and sprinkle in some colorful emojis for fun. 🎨✨

Why Manual Meshing Matters 🧐

When working with simplified models, automatic meshing often does the trick. However, for more complex structures, a manual approach is essential. The quality of your mesh can significantly impact the accuracy of your results. This is especially true when dealing with different physics scenarios like thermal analysis, structural mechanics, or fluid dynamics. 🌡️⚙️💧 For example, in thermal studies, a uniform mesh may suffice if the material is homogeneous. In contrast, structural mechanics might require a more refined mesh in stress concentration areas.

Step-by-Step Guide to Manual Meshing 🛠️📏

- Analyzing the Geometry 🔍🖼️:

- Start by examining the geometry you're working with. As an example, highlight various shapes and domains that need different meshing strategies. Identify domains that are interest for you and domains that are acting as a supporting structure.

- Creating a Mapped Surface 🌐🖌️:

- Begin by creating a mapped mesh for simple surfaces. Select the surface and use the "Generate Structured Quad Mesh" option. This method is straightforward and provides a solid foundation for further refinements.

- Refining Specific Regions 🎯🔬:

- For areas requiring finer details, such as circular regions, adjust the distribution settings. Deleting unnecessary distributions that overlap with your mapped mesh is crucial.

- Example: For a circular region, create a finer size or distribution. This enhances mesh quality in critical areas.

- Developing 3D Meshes 🧩🔲:

- Move on to creating 3D meshes using free triangular and tetrahedral elements. Select specific domains and apply size settings to achieve the desired mesh density.

- Example: Use an extra fine setting for detailed meshes, essential for accurate results.

- Optimizing Mesh for Computational Efficiency 💡⚡:

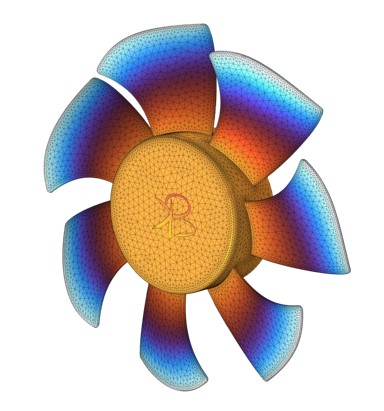

- Not all parts of your model require the same mesh density. For less critical areas, such as the wheels in Bibhatsu's example, use a coarser mesh. This optimization reduces computational load without compromising accuracy.

- Example: Adjust settings and compare element counts in different mesh densities. A coarser mesh for non-essential areas can save computational resources.

- Final Adjustments and Analysis 🔧📊:

- After meshing, review the mesh quality and make necessary adjustments. Use the build function to see changes and ensure the mesh meets your simulation's requirements.

- Example: Compare element counts and boundary elements to verify that your mesh is accurate and efficient.

Practical Tips for Successful Meshing 📝🔍

- Balance Detail and Performance ⚖️🚀: Aim for a balance between mesh detail and computational performance. Overly detailed meshes can slow down simulations without adding significant value.

- Domain-Specific Meshing 🌐🛠️: Tailor your meshing strategy based on the physics involved. Different physics may require varying meshing approaches for accurate detail capture.

- Iterative Refinement 🔄🔧: Don't hesitate to iterate on your meshing approach. Initial attempts may need refinement based on simulation outcomes.

Conclusion and Final Thoughts 💭🌟

By following these steps, you can create efficient and accurate meshes for your complex geometries, ensuring smooth simulations and reliable results. This manual meshing process allows for greater control and precision, especially in intricate models. If you found this guide helpful, be sure to subscribe to Bibhatsu’s channel for more insightful tutorials. Happy meshing! 🌟🔧✨ feel free to contact if you are struck in meshing your model 🙂

Official COMSOL resources: BLOG

you can contact us (bkacademy.in@gmail.com)

rested to Learn Engineering modelling? Check our Courses?

One reply on “Manual Mesh Tips in COMSOL Multiphysics”

[…] Meshing is essential for solving the equations numerically. In COMSOL, you can use a physics-controlled mesh to ensure the appropriate mesh density is used, especially around the interface between the two fluids. […]