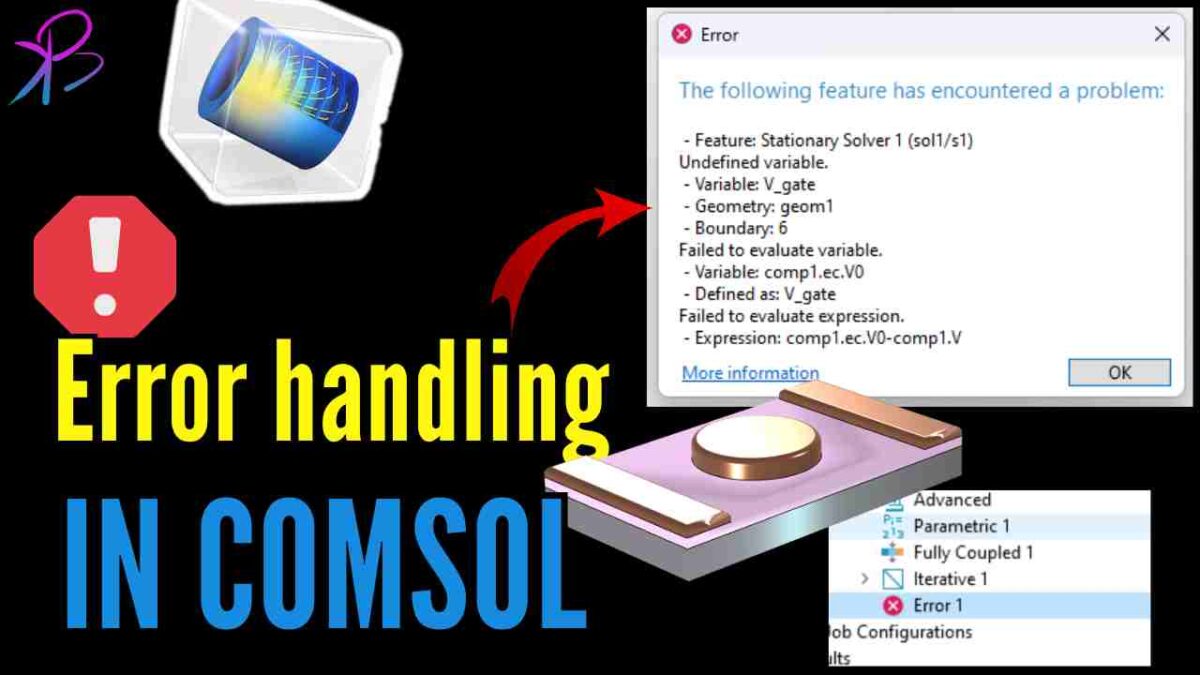

Handling Errors in COMSOL - COMSOL Multiphysics is a powerful simulation software used by engineers and scientists to model complex systems across fields like physics, chemistry, engineering, and beyond. While COMSOL is incredibly versatile, users may occasionally encounter error messages. Understanding how to effectively handle these errors can greatly improve your simulation experience and outcomes. This blog post delves into common errors in COMSOL Multiphysics and provides tips for troubleshooting them.

This YouTube Video Playlist contains videos regarding Error handling: COMSOL Error HANDLING

check out our COMSOL YouTube channel

Common Types of Errors in COMSOL

- Geometry Errors: These occur when there are issues with the creation or operation on the geometrical shapes used in your model. They might be due to overlapping geometries, small edges, or faulty imports from CAD files.

- Meshing Errors: Errors during mesh generation often happen due to the complexity of the geometry, large aspect ratios of elements, or insufficient mesh refinement.

- Solver Errors: These are related to the mathematical solvers used in COMSOL and can arise from improper solver settings, convergence issues, or the physical setup of the model itself.

- Material and Physics Setup Errors: Incorrect material properties or physics settings can lead to errors that prevent the model from running correctly.

Tips for Troubleshooting Errors

1. Check the Error Window: The first step should always be to carefully read the error messages displayed in the error window. COMSOL provides detailed descriptions that can guide you to the potential source of the problem.

2. Simplify the Model: If you're dealing with complex models, simplify them. This could mean reducing the geometric complexity, using fewer physics interfaces, or simplifying the boundary conditions. This method can help isolate the error.

3. Refine the Mesh: Many errors stem from inadequate meshing. Try refining the mesh or using a different meshing algorithm. Pay special attention to areas with high gradients or geometric intricacies.

4. Adjust Solver Settings: Solver errors often require adjustments in the solver configuration. Experiment with different solver algorithms, increase the maximum number of iterations, or adjust the convergence criteria.

5. Update Material Properties and Physics Settings: Verify that all material properties and physics settings are correct and realistic. Errors often arise from entering values outside typical ranges.

6. Use the COMSOL Knowledge Base and Forums: COMSOL’s online resources are incredibly rich. The Knowledge Base offers solutions to common problems, and the forums are a great place to seek advice from other users and COMSOL’s technical staff.

7. Build the Model Step-by-Step: Construct your model incrementally. Start by defining the geometry, then add materials, physics, and boundary conditions step-by-step, running the model at each step. This approach helps pinpoint when and where errors occur.

Conclusion

Handling errors in COMSOL Multiphysics requires a blend of technical understanding and systematic troubleshooting skills. By approaching problems methodically and making use of the resources available, you can identify the source of errors and find effective solutions. Remember, mastering error handling not only enhances your modeling skills but also deepens your understanding of the physical phenomena you are simulating.

OFFICIAL COMSOL WEBSITE : HERE

For help in modelling in any FEA, FDTD, DFT Simulation / Modelling work, you can contact us (bkcademy.in@gmail.com) or in any platform.

Interested to Learn Engineering modelling? Check our Courses?

check out our YouTube channel

u can follow us on social media

Share the resource

-.-.-.-.-.-.-.-.-.().-.-.-.-.-.-.-.-.-

© bkacademy