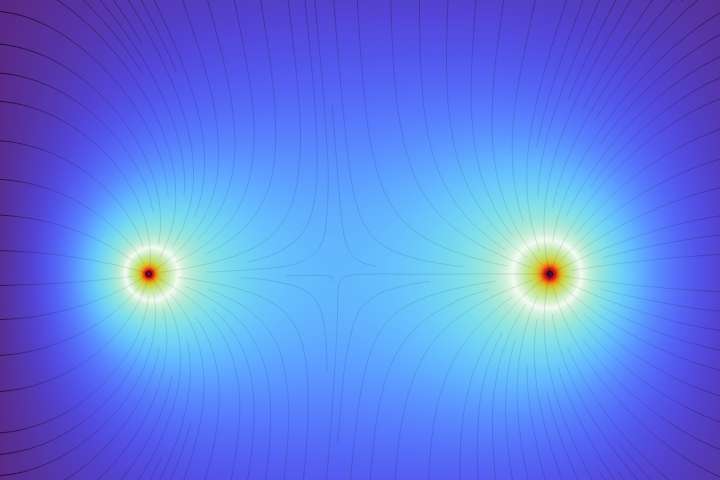

COMSOL Multiphysics has consistently provided tools that enable researchers and engineers to simulate complex phenomena with precision. With the release of version 6.3, COMSOL introduces the Electric Discharge Module, a highly specialized tool for modeling electric discharge scenarios. This module addresses a wide range of applications, from gas discharges and breakdown phenomena in liquids like transformer oil to microscale discharges in insulating polymers. By automating and simplifying the simulation process, it empowers users to explore electric discharge phenomena in greater detail than ever before. This blog delves into the features, benefits, and industrial applications of the Electric Discharge Module, highlighting how it addresses challenges that were previously difficult to tackle.

Introduction to the Electric Discharge Module

The Electric Discharge Module is a new add-on for COMSOL Multiphysics® that provides tools for simulating electric discharge events across different environments. It includes capabilities to model atmospheric pressure gas discharges, surface charge dynamics, and breakdown phenomena in both liquid and solid materials. These scenarios are critical for applications in industries such as electronics, power systems, aerospace, and materials science.

Electric discharge phenomena are complex by nature, involving physical and chemical interactions such as ionization, attachment, and recombination. Traditionally, modeling these interactions required significant manual effort and expertise. The Electric Discharge Module simplifies this process, providing users with preconfigured tools and interfaces that reduce the need for extensive setup. Its intuitive design and advanced functionality allow researchers to model discharge phenomena with accuracy and efficiency.

Key Features of the Electric Discharge Module

Comprehensive Charge Transport Models

The Electric Discharge Module incorporates widely used charge transport models that simulate the behavior of charge carriers like electrons and ions. These models are essential for accurately representing the dynamics of electric discharges. Processes such as ionization, where neutral particles become charged, and recombination, where oppositely charged particles neutralize, are modeled in detail.

This level of precision is particularly useful for applications involving high-voltage systems, where understanding charge transport is critical for predicting breakdown events. For instance, simulating charge dynamics in transformer oils can help engineers design insulation systems that are safer and more robust.

Ease of Use and Automation

A standout feature of this module is its ability to automate complex processes. Users are no longer required to manually input detailed chemical reactions or reaction rate constants in most cases. This saves time and ensures consistency, making the module accessible even to those with limited experience in electric discharge modeling.

For advanced users, the module provides flexibility through its customization options. Discharge chemistry can be tailored to specific applications using the COMSOL Desktop® interface, without the need for programming. This combination of simplicity and flexibility allows users to address a wide range of scenarios with minimal effort.

Integration with Multiphysics Models

The Electric Discharge Module is designed to work seamlessly with other COMSOL products. This integration enables users to analyze the multiphysics effects that often accompany electric discharges. For example, users can study the thermal impact of a discharge in conjunction with its electromagnetic effects. This capability is particularly valuable for applications where electric discharges interact with other physical domains, such as fluid dynamics or structural mechanics.

Applications of the Electric Discharge Module

High-Voltage Engineering

In high-voltage systems, electric discharges can lead to catastrophic failures if not properly managed. The Electric Discharge Module provides tools to simulate breakdown phenomena in transformer oils and insulating materials, helping engineers design systems that can withstand high-voltage conditions.

One key application is predicting breakdown thresholds, which are critical for ensuring the reliability of power equipment. By modeling surface charge dynamics, the module also aids in preventing arcing, a common issue in high-voltage insulators.

Electronics and Electromagnetic Compatibility

Electromagnetic interference (EMI) is a significant challenge in electronic device design, particularly as devices become smaller and more powerful. The Electric Discharge Module helps engineers analyze and mitigate the effects of electric discharges on system performance.

For instance, electrostatic discharges (ESD) can damage sensitive electronic components, while lightning-induced electromagnetic pulses can disrupt device operation. By simulating these events, the module enables engineers to develop designs that are more resilient and compliant with regulatory standards.

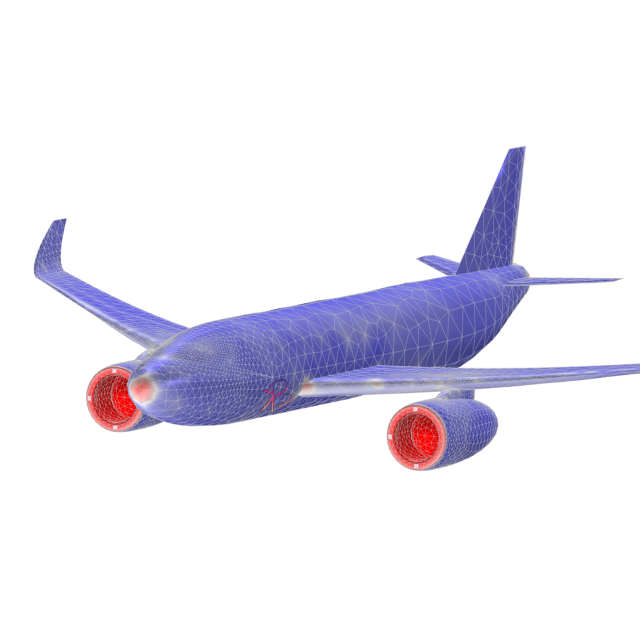

Aerospace Industry

The aerospace industry must account for electric discharge phenomena, particularly in the context of lightning strikes. Aircraft and spacecraft are frequently exposed to lightning-induced electromagnetic pulses, which can compromise safety and performance.

The Electric Discharge Module provides tools to simulate these scenarios, allowing engineers to design effective lightning protection systems. By reducing the reliance on physical testing, the module also helps lower development costs and accelerate design cycles.

MEMS and Microelectronics

Microscale discharges are a critical concern in microelectromechanical systems (MEMS) and microelectronics. These devices often operate in environments where even minor discharges can lead to failure. The Electric Discharge Module enables the simulation of microscale discharge events, providing insights that are difficult to obtain through experimental testing.

By understanding the behavior of discharges at the microscale, engineers can optimize device designs and select materials that minimize the risk of failure.

Materials Science

The module is also a valuable tool for materials scientists studying the behavior of insulating polymers and other materials under electric fields. For example, it can be used to analyze plasma-based manufacturing processes, which involve complex interactions between electric discharges and materials.

Addressing Challenges in Electric Discharge Modeling

Before the introduction of the Electric Discharge Module, many electric discharge scenarios were challenging to model due to the complexity of the underlying physics and chemistry.

Simplifying Gas Discharge Simulations

Atmospheric pressure gas discharges involve intricate processes such as ionization and recombination. Previously, simulating these events required detailed data and manual configuration, which was time-consuming and prone to errors. The Electric Discharge Module simplifies this process by providing preconfigured models that handle these interactions automatically.

Advancing High-Voltage System Design

Breakdown phenomena in transformer oils and other insulating materials are critical for the power industry. Simulating these scenarios accurately was previously difficult, requiring extensive manual input of chemical reaction data. The Electric Discharge Module eliminates this requirement, allowing engineers to focus on optimizing their designs.

Enabling Microscale Simulations

Microscale discharges in MEMS and microelectronics are notoriously difficult to study experimentally due to their size and complexity. The Electric Discharge Module provides a virtual testing environment where these events can be simulated with high precision. This capability is invaluable for advancing the design of microchips, sensors, and other devices.

Improving Efficiency and Reducing Costs

One of the most practical benefits of the Electric Discharge Module is its ability to reduce the costs associated with experimental testing and prototyping. Physical testing of electric discharges, particularly in high-voltage systems or microelectronics, is often expensive and time-consuming. By enabling virtual simulations, the module provides accurate insights at a fraction of the cost.

In addition to cost savings, the module improves efficiency by automating complex workflows. This allows users to achieve high-quality results with less effort, freeing up time for innovation and exploration.

OFFICIAL MODULE LINK

Conclusion

The Electric Discharge Module in COMSOL Multiphysics 6.3 represents a significant advancement in the field of electric discharge simulation. By simplifying complex workflows, improving accuracy, and enabling integration with other physics domains, it provides a powerful tool for researchers and engineers across industries. From high-voltage engineering and electronics to aerospace and materials science, the module opens new possibilities for innovation and efficiency. Whether you’re designing high-voltage equipment, optimizing electronic devices for EMI compliance, or exploring advanced materials, the Electric Discharge Module equips you with the tools to model electric discharge phenomena with confidence and precision.

Want to discuss? let's talk here .

Check out YouTube channel, published research

you can contact us (bkacademy.in@gmail.com)

Interested to Learn Engineering modelling Check our Courses 🙂

This article is provided for educational and informational purposes only and should not be construed as official guidance. COMSOL® and COMSOL Multiphysics® are registered trademarks or trademarks of COMSOL AB. Any other product names, trademarks, or registered trademarks mentioned are the property of their respective owners. Use of these names does not imply any affiliation, endorsement, or sponsorship. The views expressed in this article are those of the author and do not necessarily represent the views of COMSOL AB or any other organization.